RS-485 networks, also known as EIA-485 or EIA/TIA-485, are widely used in various industry applications due to their versatility and efficiency in data communication. This article provides an overview of the main features of these networks, their practical applications, and the benefits they provide.

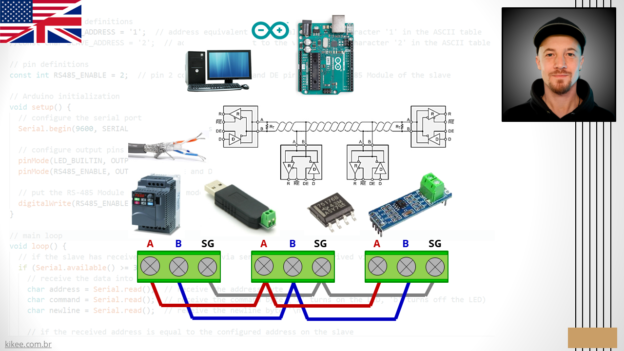

If you want to deepen your knowledge and specialize in this topic with certification, I invite you to check out this course on RS-485 networks on Udemy.

The RS-485 Standard

RS-485 is a standard defined by the ANSI/TIA/EIA-485-A standard, initially established on March 13, 1998, and reaffirmed on December 7, 2012. This standard specifies the electrical and mechanical parameters for balanced serial communication in multipoint systems. Electronic component manufacturers acquire this standard to develop circuits that are compatible with the established requirements, ensuring interoperability and compliance in the market.

Main Features

Network Topologies

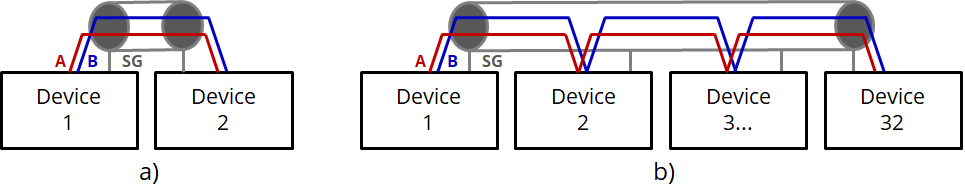

RS-485 networks support two main topologies, shown in Figure 1. In all cases, signals A and B are used for transmitting differential voltages according to the data bits and, optionally, a ground reference wire (SG) is used. All signals A are connected together on the bus, as well as all signals B. The same is true for devices that have the SG available.

- Point-to-Point: Direct connection between two devices, such as Device 1 and Device 2. This configuration is simple and effective for direct communications without sharing the physical medium with other devices.

- Multipoint (Bus): Several devices are connected on a common bus. This topology is ideal for systems that require communication between multiple devices, allowing up to 32 devices on a single standard bus, which can be expanded to up to 256 with special transceivers.

Versatility

One of the great advantages of RS-485 is its flexibility:

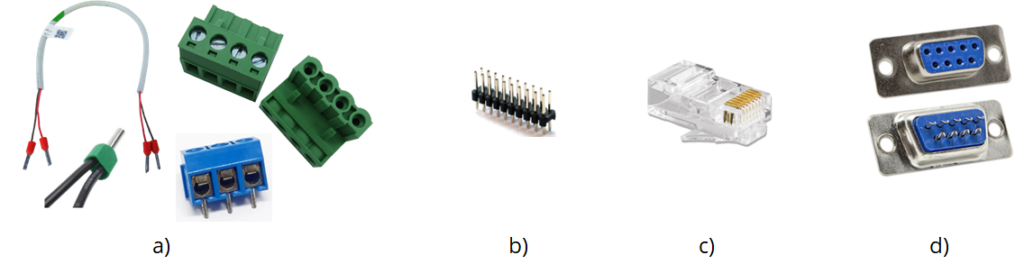

- Connectors: The standard does not define a specific type of connector, allowing the use of different models according to the application needs. Some types are shown in Figure 2.

- Communication Protocols: RS-485 only specifies the physical layer, that is, how electrical signals behave. It does not define communication protocols, leaving this choice to the developer. Protocols such as Modbus, Profibus, DMX-512 and others can be implemented over RS-485.

a) Screw terminals b) pin headers c) RJ-45 d) DB-9

Low Cost

RS-485 requires few electronic hardware components for its implementation:

- Microcontroller: Responsible for processing and controlling communication. Usually it has a UART (Serial) port which is connected to the RS-485 transceiver.

- Transceiver: Component that converts voltage levels between the microcontroller and the RS-485 network, ensuring signal compatibility and integrity.

- Termination resistors and fail-safe bias: Used to reduce the effect of noise and balance the voltage level of signals A and B on the network.

This simplicity results in a reduced cost, making RS-485 an economical option for several applications. Equipment with this type of network is more affordable when compared to those with protocols such as EtherNet/IP, ProfiNet and others.

Communication Rates and Range

RS-485 offers an excellent relationship between communication speed and distance:

- Up to 1,200 meters: At rates below 100 kbps, it is possible to reach distances of up to 1,200 meters, ideal for large industrial installations.

- High Speeds: For shorter distances, such as 50 meters, it is possible to reach rates of up to 2 Mbps, and at 6 meters, up to 10 Mbps. These use cases require a certain amount of care and are normally found in Profibus DP networks.

This flexibility allows RS-485 to be adapted to the specific needs of each project.

High Noise Immunity

RS-485’s robustness in noisy environments is achieved through:

- Twisted Pair Cable: Uses twisted wires to reduce electromagnetic interference, since induced noise affects both wires in a similar manner, allowing them to be canceled in the cable.

- Differential Communication: Transmits signals with differential voltages in signals A and B, which facilitates the elimination of common noise in the receiver circuit.

- Ground Reference (SG): The use of a ground wire as a voltage reference for transceivers improves signal stability and reduces problems caused by potential differences between devices.

- Shielding and Grounding: Additional cable shielding and proper grounding techniques provide an extra layer of protection against external interference.

Network Topology

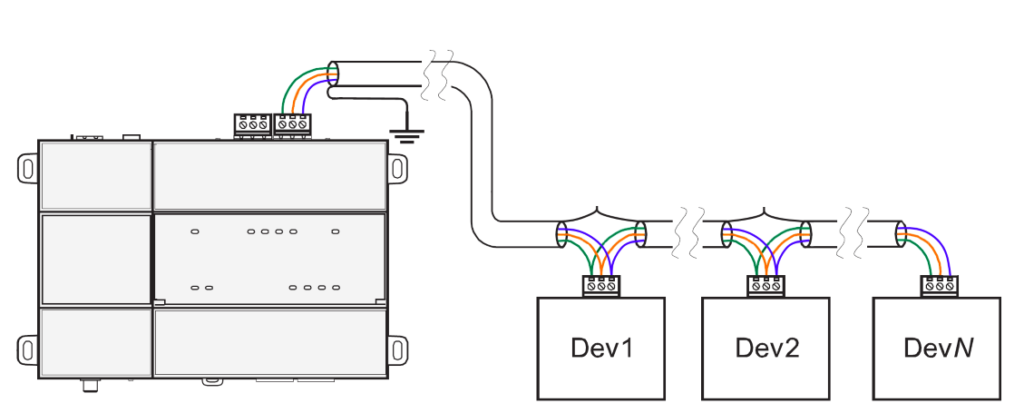

The recommended topology is Daisy Chain, where the connections of signals A, B and SG in the bus devices are made close to the connection terminals. Figure 3 shows one of the recommended installation methods to maintain high reliability.

Source: https://know.innon.com/howtowire-non-optoisolated

Half Duplex Communication

In RS-485, communication is half duplex, which means that only one device can transmit on the bus at a time. To coordinate access and avoid collisions, it is necessary to implement a control mechanism, such as:

- Master-Slave Protocol: A master device initiates communications, sending requests to slaves, which respond as requested. Protocols such as Modbus RTU and Profibus DP use this model. This approach ensures organized and efficient communication between connected devices.

Applications in Industrial Automation

RS-485 is widely used in automation devices and systems due to its favorable characteristics:

- Programmable Logic Controllers (PLCs): Many PLCs have integrated RS-485 ports or expansion modules, facilitating communication with other devices.

- Human-Machine Interfaces (HMIs): HMIs use RS-485 to exchange information with PLCs and other control equipment.

- Frequency Inverters: Allow precise control of electric motors through commands sent via RS-485.

- Remote Input and Output Modules: Sensors, actuators and other field devices can be connected to the control system using RS-485, simplifying the infrastructure and reducing costs.

Other Protocols and Applications

- DH-485: Used in Allen-Bradley equipment, it is a protocol that operates over RS-485 in specific industrial applications.

- DMX-512: Widely used in professional lighting to control luminaires and special effects devices. Each piece of equipment receives an address and is controlled by a central panel via RS-485.

- Closed Circuit TV (CCTV): In systems that do not use Ethernet, RS-485 is used to control PTZ (Pan-Tilt-Zoom) cameras, allowing focus, movement and zoom adjustments from a control center.

Conclusion

RS-485 remains a solid choice for many industrial and commercial applications, offering a balance between performance, cost, and robustness. Its ability to operate in harsh environments and support long communication distances still make it attractive in many systems.

If you want to master RS-485 and apply it effectively in your projects, I offer a course on Udemy that introduces you to the necessary knowledge and skills. Learn about the technical details, best installation practices, communication protocols, and develop practices using low-cost components such as Arduino and RS-485 modules. Learn more about the RS-485 Networks Course by accessing the Course Link on Udemy.

References

The course is based on a vast bibliography which includes, among others:

CONTROL SOLUTIONS. RS-485 FAQ – Control Solutions. www.csimn.com. Disponível em: <https://www.csimn.com/CSI_pages/RS-485-FAQ.html>. Acesso em: 23 out. 2023.

EEP – ELECTRICAL ENGINEERING PORTAL. 9 rules for correct cabling of the Modbus RS485 communication systems. EEP – Electrical Engineering Portal. Disponível em: <https://electrical-engineering-portal.com/correct-cabling-modbus-rs485>.

EVERY CONTROL SOLUTIONS. Every Control – Controladores de temperatuta, umidade, pressão e tempo – Boletins. www.everycontrol.com.br. Disponível em: <https://www.everycontrol.com.br/portal/index.php/boletins>. Acesso em: 23 out. 2023.

IF TOOLS. Serial Analyzers for RS232 and RS485. www.iftools.com. Disponível em: <https://www.iftools.com/analyzer/index.en.php>. Acesso em: 23 out. 2023.

INNON. How do I wire RS485 devices? know.innon.com. Disponível em: <https://know.innon.com/howtowire-non-optoisolated>. Acesso em: 23 out. 2023.

MACKAY, Steve ; AL, Et. Practical industrial data networks : design, installation and troubleshooting. Oxford ; Burlington: Newnes, 2004.

MAXIM. Full Guide to Serial Communication Protocol and Our RS-485 |. www.maximintegrated.com. Disponível em: <https://www.maximintegrated.com/en/design/technical-documents/app-notes/3/3884.html>.

MAXIM. General Description PART NUMBER HALF/FULL DUPLEX DATA RATE (Mbps). [s.l.: s.n.], 2014. Disponível em: <https://datasheets.maximintegrated.com/en/ds/MAX1487-MAX491.pdf>.

MAXIM. HOW FAR AND HOW FAST CAN YOU GO WITH RS-485? [s.l.: s.n.], 2014. Disponível em: <https://pdfserv.maximintegrated.com/en/an/AN3884.pdf>.

MAXIM. RS-485 Cable Specification Guide | Maxim Integrated. www.maximintegrated.com. Disponível em: <https://www.maximintegrated.com/en/design/technical-documents/tutorials/7/763.html>.

NOVUS. NOVUS PRODUTOS ELETRONICOS LTDA RS485 & RS422 Basics. [s.l.: s.n., s.d.]. Disponível em: <https://www.novusautomation.com/downloads/Arquivos/rs485%20&%20rs422%20basics%20-%20english.pdf>.

SOLTERO, Manny; ZHANG, Jing; COCKRIL, Chris; et al. Application Report RS-422 and RS-485 Standards Overview and System Configurations. [s.l.: s.n.], 2002. Disponível em: <https://www.ti.com/lit/an/slla070d/slla070d.pdf>.

TEXAS INSTRUMENTS. SN75176B data sheet, product information and support | TI.com. www.ti.com. Disponível em: <https://www.ti.com/product/SN75176B>. Acesso em: 23 out. 2023.

WIKIPEDIA CONTRIBUTORS. RS-485. Wikipedia. Disponível em: <https://en.wikipedia.org/wiki/RS-485>.